產(chǎn)品中心

新聞資訊

- 實用技巧:雙軸攪拌機日常維護保養(yǎng)全攻略

- 深度剖析:有機肥攪拌機如何實現(xiàn)肥料的完美融合

- 有機肥加工過程中,立式攪拌機的操作流程

- 有機肥雙軸攪拌機對成品質(zhì)量的影響

- 雙軸攪拌機的保養(yǎng)策略

聯(lián)系我們

手機:18603847333

電話:

郵箱:807586248@qq.com

地址:河南省鄭州市滎陽市新310國道任莊村

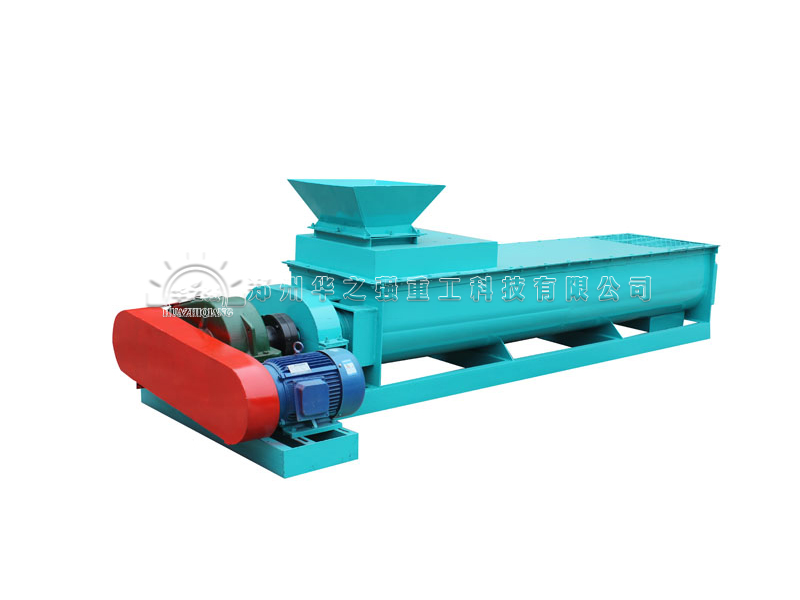

雙軸攪拌機

用途及特點:

雙軸攪拌機是通過兩組帶有螺旋葉片的軸相對轉動,加水對粉狀物料進行噴濕攪拌輸送,使粉狀物料達到可控濕度。該設備主要適用于肥料行業(yè)原料的加濕混合,使物料充分攪拌,并兼具輸送功能。當定量的生料粉由下料口流入攪拌槽中,經(jīng)若干個具有相對壓力的水霧化撒向生料粉,由定性長度的軸經(jīng)攪拌葉攪勻后形成含水一致的球核。整個攪拌分為霧化區(qū),拌勻區(qū),卸料區(qū)三個區(qū)域。攪拌葉耐磨性能好,使用壽命長。

Double Axis Mixer

Use and Features:

The double axis mixer is rotated through two groups of screw shafts with spiral blade, and water is added water to the powder material for spraying wet mixing transportation, so that powdery material can achieve controllable humidity. The equipment is mainly suitable for humidification and mixing of raw materials in the fertilizer industry, so that the materials are fully mixing and this machine have the function of conveying too. When the quantity of raw material is poured into the mixing tank from the outlet, the raw material is atomized by a number of water with relative pressure, which is stirred by the mixing shaft of the qualitative length to form a uniform water-containing core. The whole agitation is divided into three areas: atomization area, mixing area and discharge area. The agitator leaves have well wear resistance and long service life.

構造及工作原理

雙軸攪拌機由驅動部分與本體部分組成。

驅動部分由電機、聯(lián)軸器、減速機組成。然后由滾子鏈帶動本體上的主動軸轉動,并通過主動軸上的齒輪,帶動從動軸上的齒輪及從動軸同時轉動。

當物料由進料口進入攪拌槽后,由裝有螺旋葉片的主、從動軸螺旋推動物料且攪拌后,由出料口送出,然后由運輸機械裝走。

物料加水是與物料攪拌同時進行的,水是由進水管及噴嘴組成的噴水裝置供給的。

客服QQ

客服QQ